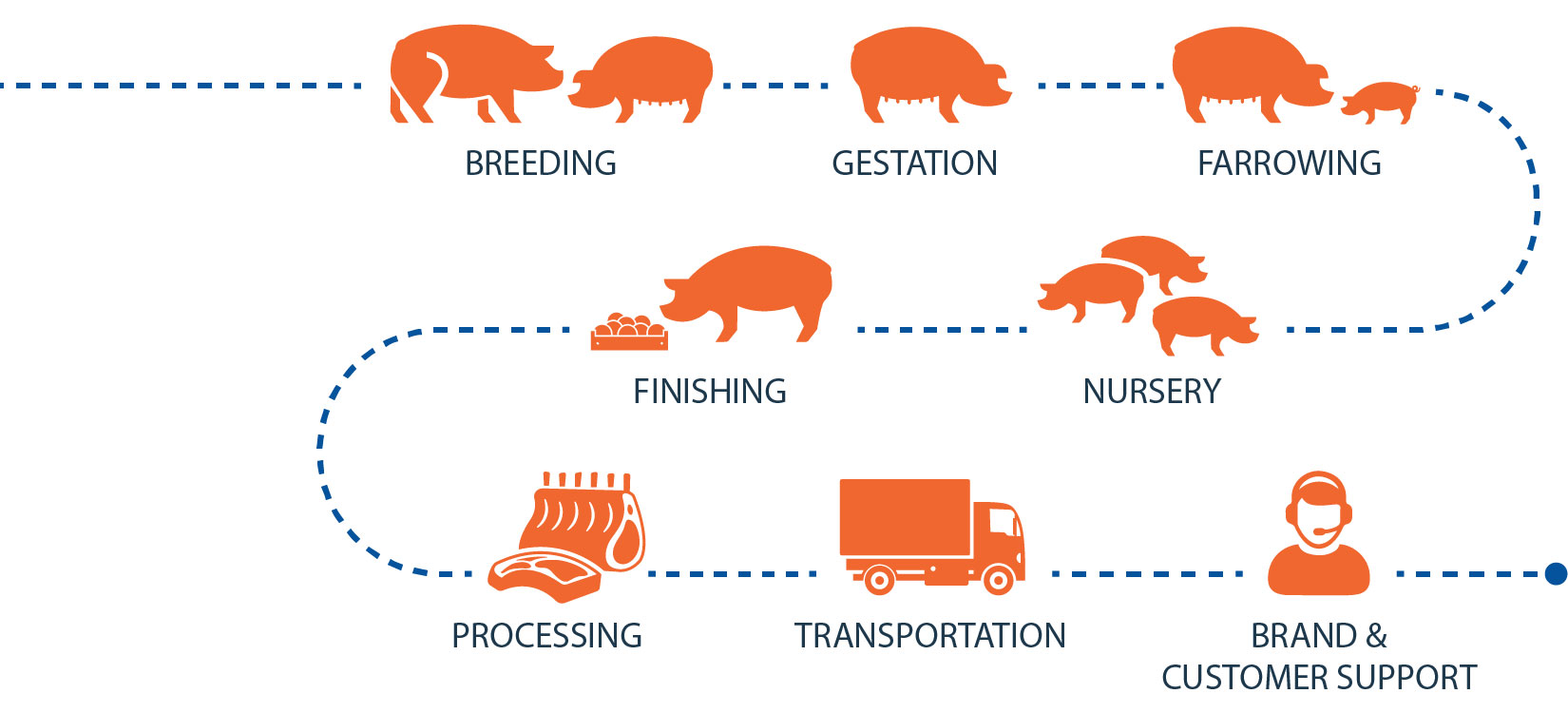

From Pigs to Pork: The Lifecycle of Seaboard Foods’ Pork Products

At Seaboard Foods, we take pride in feeding people. Our connectivity across every step of raising and caring for pigs for pork — from breeding to supermarkets to restaurants — ensures we raise healthy pigs and deliver high-quality, delicious pork.

BREEDING

It starts with superior genetics to raise healthy animals.

GESTATION

Sows are moved to our gestation barns where they receive specialized veterinary care and nutrition.

FARROWING

Sows typically give birth to 10-12 piglets and nurse their offspring for about 3 weeks.

Later we move our male and female piglets to nursery barns where they receive daily care in open pens with other pigs from their sow barn.

NURSERY

Living in open pens with peers from the nursery to ensure comfort and well-being, our pigs reach full weight in 20 weeks.

FINISHING

Pigs are processed in state-of-the art plants to ensure pork safety and consistent quality.

PROCESSING

Seaboard Foods is committed to producing and shipping safe quality pork.

TRANSPORTATION

BRAND & CUSTOMER SUPPORT

About Seaboard Foods

Since the pork we make is served on tables around the world, we foster a culture of asking why. To learn more facts about Seaboard Foods as a company, click here.