Our History: A Legacy of Quality and Innovation

Since we opened for business in the 1990s, Seaboard Foods has built a strong foundation for producing pork for tables all over the world. Born of a family-owned business, we continue the tradition of working together to make our products the best they can be.

1990

Known as Seaboard Farms in the beginning, Seaboard Foods, a division of Seaboard Corporation, started building farms in 1990s. Today, farm operations are located in Oklahoma, Kansas, Colorado, Texas and Iowa and consist of genetic and commercial breeding, farrowing, nursery and finishing farms with more than 2,000 dedicated farm employees.

1995

Seaboard Foods’ state-of-the-art processing facility in Guymon, Okla., opened in 1995.

1997

The Guymon, Okla., plant has operated at full capacity since 1997, processing more than 20,000 hogs a day and approximately 1.4 billion pounds of pork annually, holding a position as a Top 10 pork processor.

2003

Seaboard Foods breaks ground in the area of animal well-being and handling with unannounced third-party animal welfare audits conducted by Farm Animal Care Training and Auditing, LCC (FACTA).

2005

Daily’s Premium Meats and its two bacon processing plants located in Salt Lake City and Missoula, Mont., joined the Seaboard Foods connected food system. The two plants produce more than 100 million pounds of raw and precooked bacon products each year. With the addition of this further processed pork division, Seaboard Farms changes its name to Seaboard Foods.

2006

Seaboard Foods begins to market and sell fresh pork products produced at a new pork processing plant located in St. Joseph, Mo. The plant is owned and operated by Triumph Foods. The producer-owners of the Triumph Foods plant have aligned with Seaboard Foods and follow a controlled, connected pork production model similar to the Guymon, Okla., food system to ensure product consistency between the two plants. Both the Guymon and St. Joseph pork processing plants supply Daily's with raw materials to produce premium center cut bacon.

2007

The National Pork Board and The National Hog Farmer magazine named Seaboard Foods' Wakefield Farm as the 2007 Pork Industry Environmental Steward. The farm uses a seven-stage system to manage manure, with a composting site that produces environmentally friendly potting soil used for gardens. The farm plants grass and wheat around the perimeter, providing cover and forage for wildlife.

2008

Seaboard Foods celebrated the Grand Opening of High Plains Bioenergy, an alternative energy plant creating biodiesel using pork fat from the Seaboard Foods system. Today, High Plains Bioenergy is known as Seaboard Energy and produces nearly 35 million gallons of biodiesel.

2012

Seaboard Foods started construction on a new feed manufacturing facility in Holyoke, Colo., and finished construction in 2012. This became Seaboard Foods’ seventh feed mill. Today, eight centrally located feed mills in Oklahoma, Kansas, Texas, Iowa and Colorado make up to 15 proprietary feed rations for the pigs on more than 870 Seaboard Foods’ company-owned and contract farms.

2014

High Plains Bioenergy celebrates the grand opening of a fast-fill CNG station located across the road from the Seaboard Foods Guymon, Okla., processing facility.

2014

Triumph Foods purchases a 50 percent interest in Daily's Premium Meats, the processed meats division of Seaboard Foods. The transaction increased the partnership between Triumph Foods and Seaboard Foods, while enabling Daily's to have a supply of high-quality raw materials.

2015

Seaboard Foods and Triumph Foods announced together the new joint venture Seaboard Triumph Foods and the construction of a new pork processing facility in Sioux City, Iowa. Site work began in fall of 2015 and the plant opened September 2017.

2016

Daily's Premium Meats celebrated the opening of the third bacon processing plant in St. Joseph, Mo., with a ribbon cutting and virtual tour.

HPB-St. Joe Biodiesel celebrated the opening of a biodiesel plant in St. Joseph, Mo., using vegetable oils and animal fats as a feedstock.

2017

The innovative processing plant, Seaboard Triumph Foods, a joint venture between Seaboard Foods and Triumph Foods, opens its doors in Sioux City, Iowa.

2019

Seaboard Energy, formerly known as High Plains Bioenergy, becomes the newest company for Seaboard Corporation. With the success of the former entity High Plains Bioenergy, a subsidiary of Seaboard Foods, and the potential growth opportunity in renewable energy, Seaboard Energy was created to expand Seaboard's energy business.

2020

Seaboard Foods completed major renovations to the processing plant in Guymon, Okla. The multi-year expansion project added technology and additional space to boost efficiency and improve safety standards.

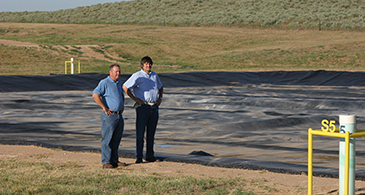

2023

Seaboard Foods officially forms Seaboard Foods RNG, which includes swine-derived and non-swine-derived renewable natural gas (RNG) projects with additional projects under construction in Oklahoma, Texas and Kansas. Covered anaerobic digester lagoons with biomethane upgrading facilities generate ultra-low carbon intensity (CI) RNG.